Production Facility

Assessment & Goal Setting

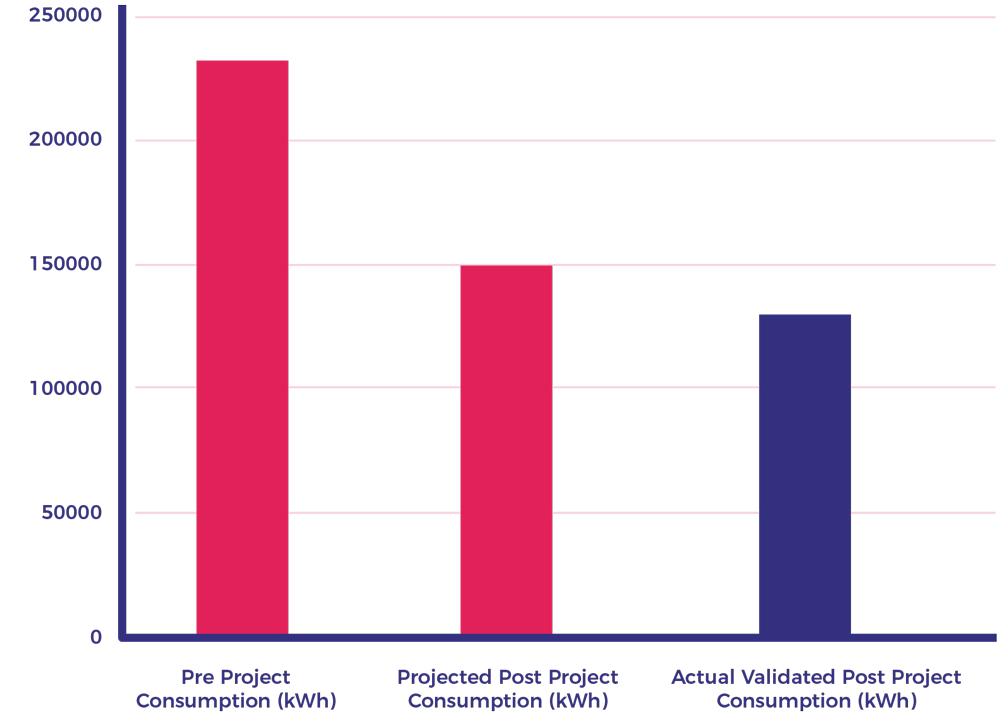

Following the installation of new packing facility Clarke Optimal were tasked with the energy saving drive within the existing building to enable the site to become a more efficient manufacturing operation.

Implement & Deliver

Assessment was conducted to ensure all assets were analysed and monitored.

Operational assessment was carried out to decide on essential and non-essential plant. Essential plant was optimised to maximise efficiency whilst maintaining the requirements for the environment. Redundant plant was decommissioned to realise maximum energy savings.

Achieve Goals & Analyse

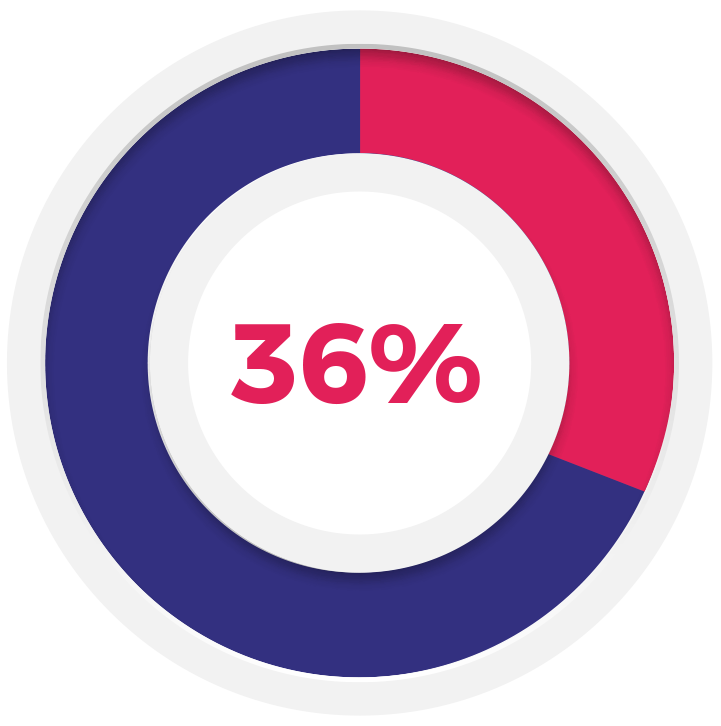

Huge energy savings have been verified and realised from the assessment carried out.

| Area A1 | Area A2 | Area B | Area C4 | |

|---|---|---|---|---|

| Co2 Savings (Tonnes) | 121.3 | 61.4 | 64.5 | 710.1 |

| Grand Total Cost Savings | £80,637 | £33,636 | £52,923 | £377,029 |

| Return On Investment (ROI) Months | 2.9 | 2.0 | 4.0 | 8.0 |

Achieve Goals & Analyse

Huge energy savings have been verified and realised from the assessment carried out.

Co2 Savings (Tonnes)

Area A1 121.3

Area A2 61.4

Area B 64.5

Area C4 710.1

Grand Total Cost Savings

Area A1 £80,637

Area A2 £33,636

Area B £52,923

Area C4 £377,029

Return On Investment (ROI) Months

Area A1 2.9

Area A2 2.0

Area B 4.0

Area C4 8.0

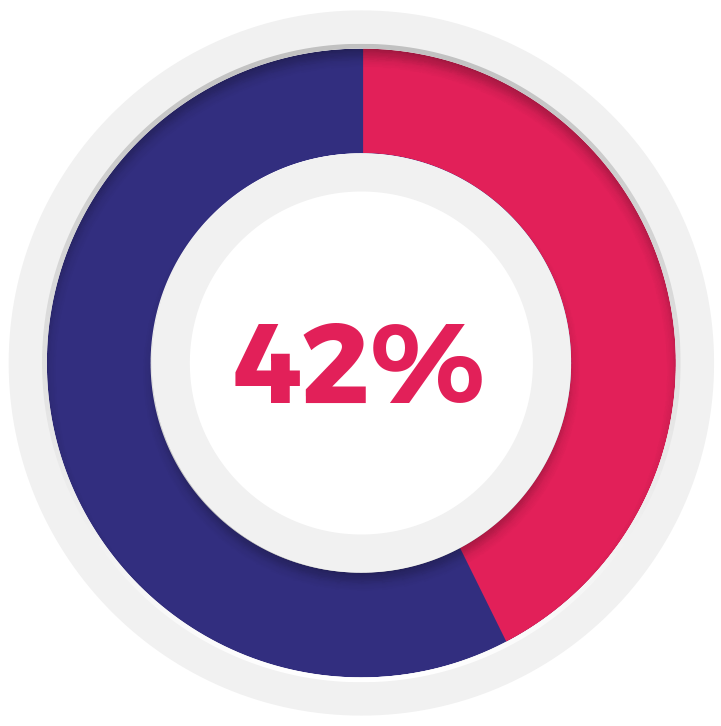

Pharma Production Facility 42% Reduction

Calculated Predicted Energy Savings